Product Overview

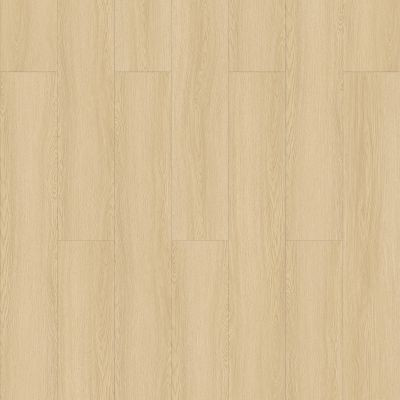

TUFFCORE LOOSELAY (WATERPROOF)

COLORS / PRODUCT DATA

#1600 RE-LLY – #1607 RE-LLY

-

Type: TC Looselay (EBR)

-

SF/Box: 29.58

-

Wear Layer: 0.5mm

-

Thick: 5mm

-

Width: 9"

-

Length: 60"

-

Length Type: FPL

-

Box/Plt: 48

-

Box Wgt: 23.19 lbs

-

SF/Plt: 1,419.84 SF

-

Pallet Wgt: 1,143 lbs

#1608 RE-LLY – #1609 RE-LLY

-

Type: TC Looselay (SM)

-

SF/Box: 29.58

-

Wear Layer: 0.5mm

-

Thick: 5mm

-

Width: 9"

-

Length: 60"

-

Length Type: FPL

-

Box/Plt: 48

-

Box Wgt: 23.19 lbs

-

SF/Plt: 1,419.84 SF

-

Pallet Wgt: 1,143 lbs

APPROVED INSTALLATION

-

Nail ❌

-

Glue Only ✅

-

Float ❌

-

Click ❌

-

Below Grade ❌

-

Radiant Heat ❌

COMPOSITION

TOP LAYER

-

Type: PVC

-

Thickness: 0.5mm

-

Finish: Registered Embossed (EBR) / Smooth (SM)

-

Gloss Levels: 4% – 6%

CORE

-

Type: PVC

-

Thickness: 4.3mm

-

Color: Black

-

Density: >960kg/m³

BACKING

-

Type: PVC

-

Thickness: 0.2mm

EDGE PROFILE

-

Bevel: Painted Bevel (1.2mm Wide)

JOINT SYSTEM

-

N/A

INSTALLATION

-

Pattern Repeat: 8+

-

Install Pattern: N/A

-

Uses: Residential – Commercial

ADVANCED TECHNICAL

-

Impact Sound Reduction: IIC Rating 42dB

-

Sound Transmission Reduction: STC Rating 55dB

-

Maintenance: Bona Hard-Surface Floor Cleaner

-

Formaldehyde Emission: CARB Phase 2 Compliant

-

Fire Rating: A+ Rated

-

Ortho-Phthalates: Ortho-Phthalate Free, Prop 65

-

Swelling: N/A

-

Humidity Change: N/A

-

Reaction to Fire: EN 14041 / Class Bfl-S1

-

Slip Resistance: EN 14041 / Class DS

-

Stain Resistance: ASTM F925-13, PASS

-

Wear Resistance: ASTM F2399-18, PASS

GENERAL SUBSTRATE REQUIREMENTS

Structurally sound, well bonded, flat to within 3/16" in 10' radius or 1/8" in 6' radius, vertical deflection cannot exceed 1/4" in 10' radius, or more than 1/16" between the floor joists.

SUBSTRATE REQUIREMENTS

APPROVED SUBSTRATES (BUILDERS CHOICE DRYBACK)

(Glue down options)

Subfloors over joist systems must be TECO or APA subfloor grade CDX plywood/OSB. The joist span cannot exceed 16" on center when using 5/8" plywood or 3/4" subfloor, or 19.2" on center when using 3/4" plywood or 7/8" OSB, or 24" on center when using 7/8" plywood or 1" sub-OSB.

Additional approved substrates: Cured concrete over 3000 PSI, cured gypsum cement backer board, cementitious & anhydrite screeds, radiant heated subfloors that do not exceed 85°F surface temperature, & gypsum or lightweight concrete (primed with TuffGrip LS Primer).

WOOD SUBFLOOR (EMC) MOISTURE CONTENT REQUIREMENTS

The subfloor must not exceed 12% MC (moisture content). Wood subfloors must be suspended a minimum of 18" from the ground with adequate ventilation. The ground surface of the crawl space must be covered with a minimum 6 mil plastic (puncture resistant) vapor barrier.

CONCRETE & GYPCRETE MOISTURE EMISSIONS, RH, & pH REQUIREMENTS

(For ON or ABOVE GRADE)

Glue down – Perform a calcium chloride test. It must not exceed 3 pounds per 1,000 square feet per 24 hours. When tested in accordance with ASTM F1869. RH testing must be performed in accordance with ASTM F2170. If the substrate tests are above or below these requirements, you must use a moisture mitigation or sealant system to prevent moisture related issues.

JOBSITE CONDITION RANGES

The jobsite RH must be maintained between 35%–85%, & the room temperature between 65°F–85°F prior to, during, & after installation.

ACCLIMATION TIMEFRAME

Minimum 48 hours to reach room temperatures between 65°F–85°F.

CAN WE INSTALL A CUSHION UNDERNEATH THE FLOOR?

Cushion is not compatible.

RECOMMENDED GLUE

Approved for substrates listed above. (Follow all glue installation guidelines)

Glue Down: Temperature must be 65°–85°F

TUFFGRIP PS-39 – Modified Transitional PSA; Wood Adhesive

COMPLIANCE

This series has been tested and contains the following certifications:

-

FloorScore®

-

GreenGuard Gold®

AVAILABLE COLORS

#1600 RE-LLY

#1601 RE-LLY

#1602 RE-LLY

#1603 RE-LLY

#1604 RE-LLY

#1605 RE-LLY

#1606 RE-LLY

#1607 RE-LLY

#1608 RE-LLY

#1609 RE-LLY